Harsh Environments Pneumatic Cylinders

In harsh industrial settings such as food and beverage or marine applications, pneumatic cylinders are often exposed to moisture. Without proper protection, this can lead to rapid wear and malfunctions in machine parts, resulting in increased maintenance, replacement expenses, and downtime. Opting for a durable and corrosion-resistant cylinder, such as our CR Series, will effectively shield your equipment from corrosion.

American's Original Series and All Stainless CR® air cylinders are built to endure exposure to a variety of moisture, lubricants, and specific solvents. These corrosion-resistant air cylinders are constructed with major components made of acetal resin and stainless steel. The available bore sizes include 9/16", 3/4", 1-1/16", 1-1/2", 2", 2-1/2" (exclusive to Original Series), and 3" (exclusive to All Stainless Series). Explore the versatility of our corrosion-resistant (CR) air cylinders, available in various types to meet your specific needs.

Corrosion Resistant Air Cylinder Types

-

Single Acting (Original CR Series Only)

-

Double Acting

-

Volume Chambers

-

Accessories

Mount Options For CR Series Cylinders

- Nose Mount

- Universal Mount

- Double Rod End

Available Options For CR Series Cylinders

- Bore Sizes From 9/16" thru 3"

- Stroke Selection

- Bumper Option

- Magnetic Piston

- Seal Material

- Buna N

- FDA Approved

- FKM

- Rear Head Options

- Lubrication Type

- Rod End Options

STANDARD FEATURES AND BENEFITS

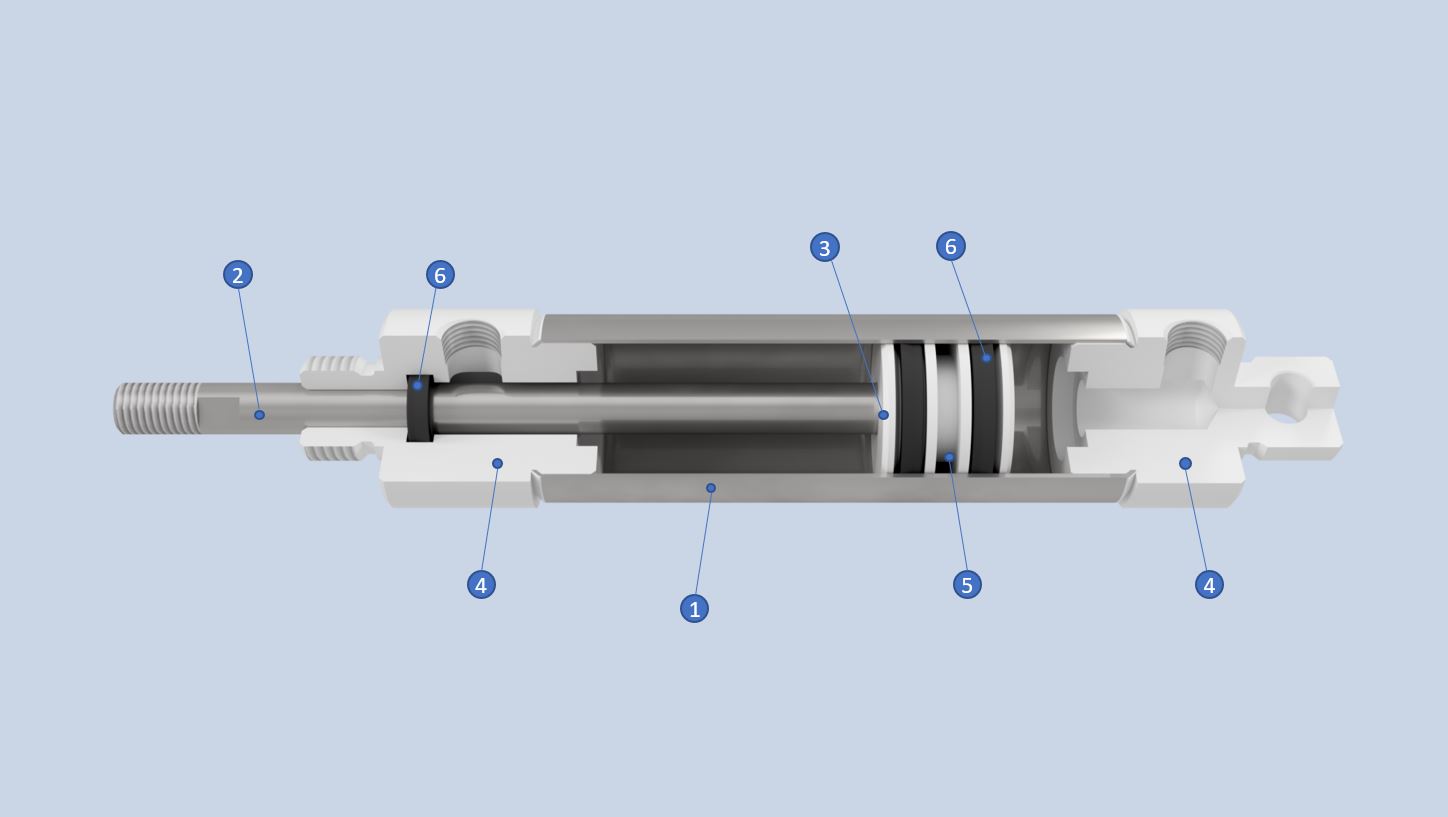

Original CR Series

Stainless Steel Cylinder Body

Type 304 Stainless Steel manufactured to special mill specifications and tolerances to insure a long cylinder life.

Stainless Steel Rod

Ground & Polished Type 303 Stainless Steel rods are standard. All rods have wrench flats and stress relief grooves.

Piston Rod Assembly

Piston rods are threaded, anaerobically sealed, and machine staked into the piston for triple protection.

End Caps & Piston

Made of acetal resin, a crystalline thermoplastic co-polymer made by the polymerization of formaldehyde.

Springs

Springs for spring action cylinders are made from stainless steel and designed for millions of cycles. Special spring forces are available.

Buna-N U-Cup Rod & Piston Seals

Pressure energized lip type seals provide low breakaway friction and maximize cylinder life expectancy. Standard Buna-N seals are recommended for operating temperatures of -20°F (-25°C) to 200°F (95°C). FDA approved seals are available as an option (-35). Additional special seal compounds and lubricants are available upon request

Rod Seal

Precision machined rod seal groove provides a smooth sealing surface while positively retaining the seal without requiring additional components and relying on press fit containment.

Prelubricated

All cylinders are factory lubricated with a special high endurance oil mixture. FDA approved lubrication is standard with the FDA seal option (-35).

Pre-Tested

The quality of each cylinder is assured by testing each unit for leakage prior to shipment. Quality control provides added value to American cylinders

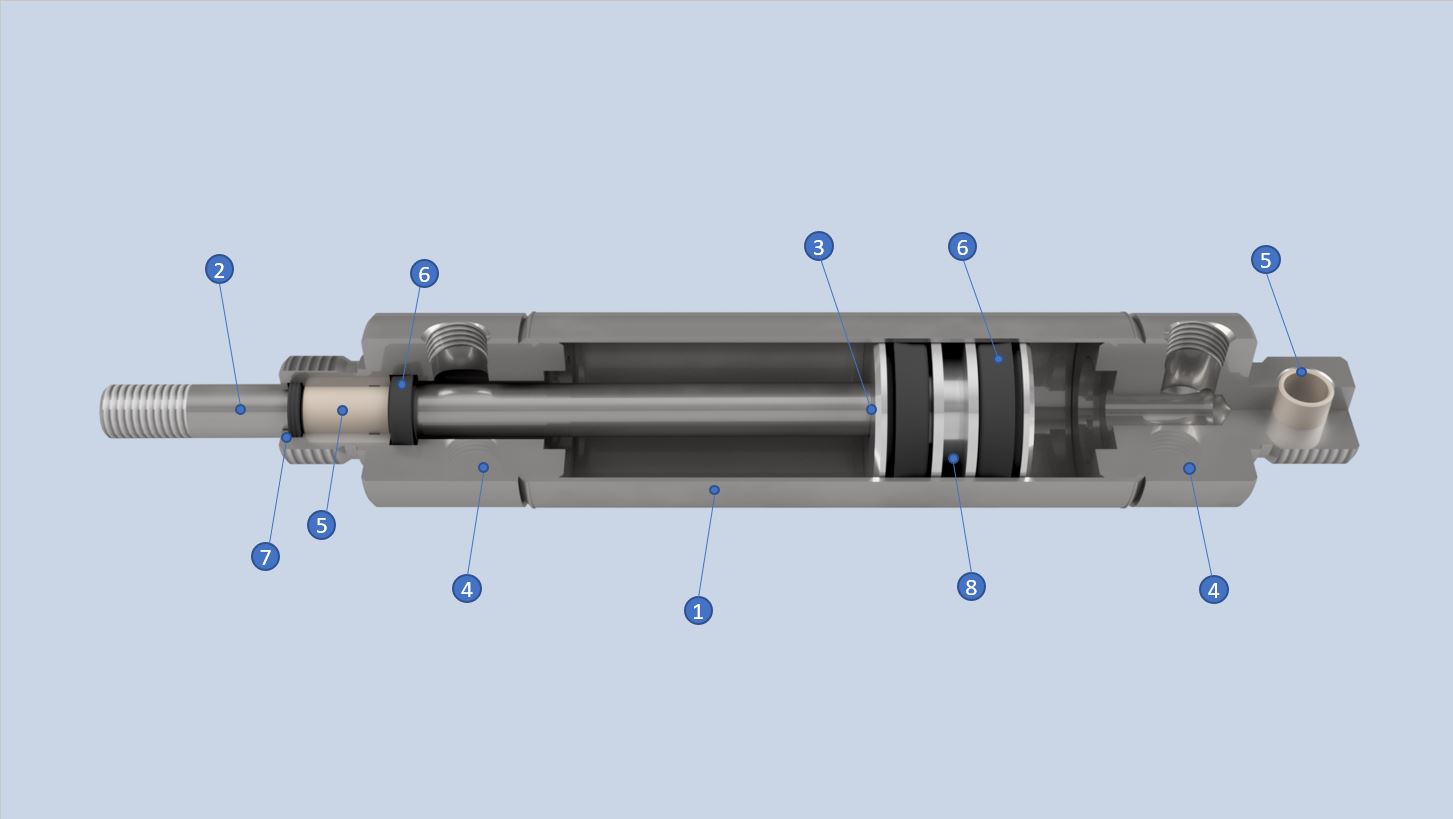

All Stainless CR Series

Stainless Steel Cylinder Body

Type 304 Stainless Steel manufactured to special mill specifications and tolerances to insure a long cylinder life.

Stainless Steel Rod

Ground & Polished Type 303 Stainless Steel rods are standard.

Piston Rod Assembly

End caps are made of 303 stainless steel.

End Caps

The quality of each cylinder is assured by testing each unit for leakage prior to shipment. Quality control provides added value to American cylinders

Rod/Pivot Bushings:

All bushings used are an FDA complaint composite material. They are compatible with all seal/lubrication options.

Buna-N U-Cup Rod & Piston Seals

Pressure energized lip type seals provide low breakaway friction and maximize cylinder life expectancy. Standard Buna-N seals are recommended for operating temperatures of -20°F (-25°C) to 200°F (95°C). FDA approved seals are available as an option (-35).

Urethane Wiper Seal

Precision machined rod seal groove provides a smooth sealing surface while positively retaining the seal without requiring additional components and relying on press fit containment.

Piston

Pistons are made of a high strength aluminum alloy. Note: Pistons on double rod end models are a brass alloy material.

Prelubricated

All cylinders are factory lubricated with an FDA approved grease as standard. A high temp grease is substituted when the high temp FKM seal option (-31) is selected.

Pre-Tested

The quality of each cylinder is assured by testing each unit for leakage prior to shipment. Quality control provides added value to American cylinders.