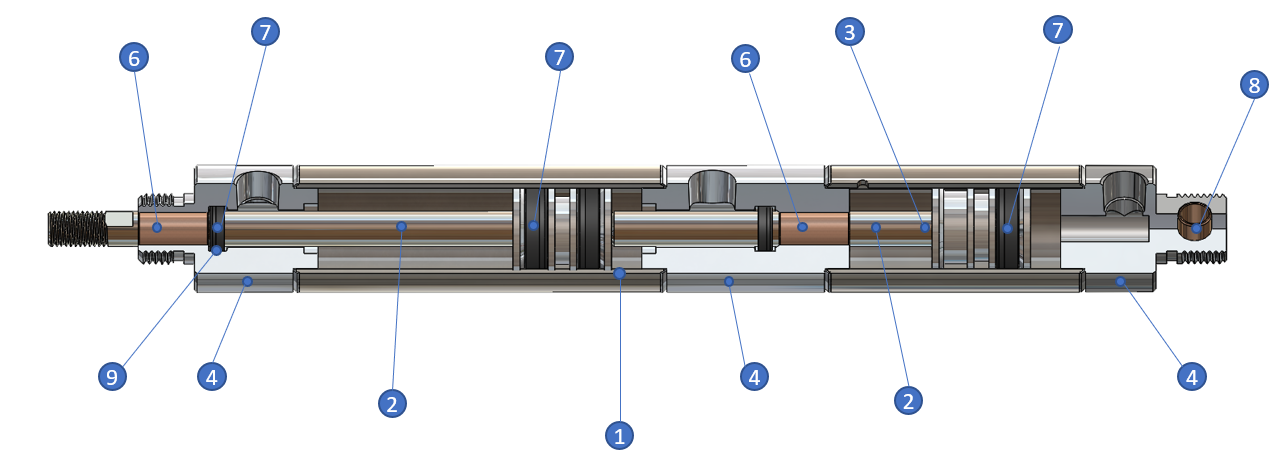

Non Repairable 3 Position Cylinders

American Cylinder's Three Position Cylinders, where precision meets durability. We offer non-repairable, stainless steel, aluminum, magnetic, corrosion-resistant, and three position cylinder solutions. Crafted with stainless steel bodies and rods, our cylinders ensure long-lasting performance. Triple-protected piston rod assemblies, high-strength aluminum components, and optional internal magnets for precise switch actuation make our cylinders stand out. Standard rod guides, low-friction seals, and precision-machined grooves enhance functionality. Each unit is pre-lubricated and rigorously pre-tested for quality assurance. Choose American Cylinder for reliable, high-performance solutions.

Non-Repairable 3 Position cylinders can be used when multiple positions are needed for an application. They can also be used as a multiple power cylinder if specified with a matching initial stroke and total stroke.

STANDARD FEATURES AND BENEFITS

Stainless Steel Cylinder Body

Type 304 Stainless Steel manufactured to special mill specifications and tolerances to insure a long cylinder life.

Stainless Steel Rod

Ground & Polished Type 303 Stainless Steel rods are standard on the Three Position Series. All rods 1/4" diameter and larger have wrench flats and stress relief grooves.

Piston Rod Assembly

Piston rods are threaded, anaerobically sealed, and machine staked into the piston for triple protection.

End Caps, Piston, Center Section

High strength aluminum alloy.

Magnet for Sensing Switch Actuation

Optional internal magnet specially designed for use with American Reed or Hall Effect switches. Used for position signaling.

Rod Guide/Center Bushing

Standard on all models. The oil impregnated sintered bronze bushing increases the life of the cylinder rod and provides a non-abrasive bearing surface.

Buna-N U-Cup Rod & Piston Seals

U-Cup seals provide low breakaway friction and maximize cylinder life expectancy. Standard Buna-N seals are recommended for operating temperatures of -20°F (-25°C) to 200°F (95°C). Fluoroelastomer seals are available for higher temperature applications. Additional special seal compounds and lubricants are available upon request.

Pivot Pin/Pivot Bushing

Stainless Steel Series cylinders are shipped with plated steel pivot pins as standard. Sintered bronze pivot bushings are available as an alternative standard option. (2" bore is supplied with pivot bushing only.)

Rod Seal

Precision machined rod seal groove provides a smooth sealing surface while positively retaining the seal without requiring additional components and relying on press fit containment.

Pre-lubricated

All cylinders are factory lubricated with a special high endurance oil mixture.

Pre-Tested

The quality of each cylinder is assured by testing each unit for leaks and tested prior to shipment. Quality control provides added value to American cylinders.