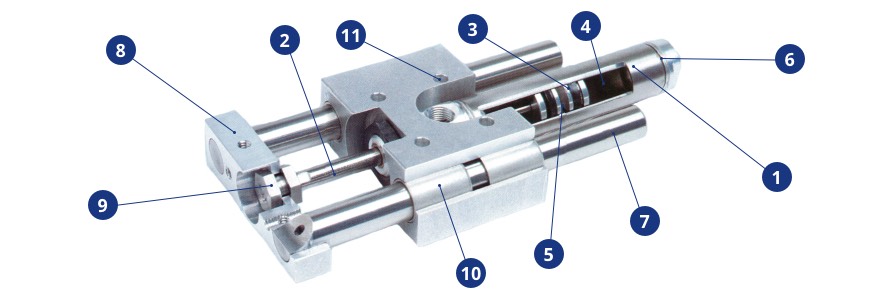

Linear Slide LSC Series Cylinders

American Cylinder's Linear Slide LSC Series Pneumatic Cylinders are engineered to provide precision, mounting flexibility, and torsional stability, making the LSC Series a preferred choice for applications where an all in one solution for load guidance is required or preferred.

For more information on our linear slide pneumatic cylinders, contact us today.

STANDARD CYLINDER BENEFITS AND FEATURES

Cylinder Body

Type 304 Stainless Steel tubing with strict specifications and tolerances to ensure longer cylinder life.

Piston Rod Assembly

Ground & Polished Type 303 Stainless Steel piston rod with special accuracy specifications is threaded, anaerobically sealed and machine staked into the piston for triple protection.

Buna-N U-Cup Rod & Piston Seals

U-Cup seals provide low breakaway friction and extended seal life. Standard Buna-N seals are recommended for operating temperatures of -20° F to 200° F. Fluoroelastomer seals are available for higher temperature applications. Additional special seal compounds and lubricants are available upon request.

Prelubricated

All cylinders are factory lubricated with a special high endurance oil.

Magnetic Piston Band

All units (except 5/16 bore) are provided with a magnetic piston band as standard for applications requiring position sensing. Solid State Switches and Reed Switches are available as accessory items.

End Caps

High strength aluminum alloy

Guide Shafts

Large diameter special accuracy Hard Chrome Plated Type 303 Stainless Steel shafts act as the inner race for the precision sleeve bearings and provide a rigid attachment for the tooling mounting bar.

Tooling Mounting Bar

Sturdy aluminum alloy, machined top and front surfaces with standard tapped mounting holes. Special configurations available upon request

Floating Coupler

Prevents cylinder rod binding ensuring longer life.

Shaft Bearings

High performance Duralon® sleeve bearings have a composite inner liner of low-friction, self-lubricating fibers with a reinforced filamentwound Fiberglass and epoxy shell to provide smooth guided motion with high load carrying capabilities.

Mounting Holes

Standard through mounting holes designed for standard cap screws. Alternative threaded mounting holes available as a standard option. (See Option "T" in Product Catalog)

Pre-Tested

The quality of each assembly is assured by testing each unit for leakage and binding resistance prior to shipment.

Series Types

- S Series

- L Series

- Switches

- Solid State

- Reed Switches

- Slide Mounting Accessories

Linear Slide Pneumatic Cylinder Options

- Stroke

- Bumper & Stop Collars

- Seal Material

- Mounting Holes

- Rear port